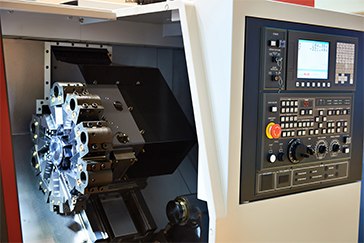

CNC Horizontal Milling Machine

In CNC milling, a machine cutting tool rotates and moves back and forth along the surface of a workpiece, removing material. A horizontal mill operates with its spindle in a horizontal position.Some of the major machine manufacturers that make CNC Horizontal Milling Machines are Haas Mills with its EC model, Mazak with ita HCN models, Okuma and lastly Kitamura

Used Horizontal Milling Machines

Below are classifications of Horizontal Mills as well as their basic components.

Classification of Horizontal Mills

- Controls: Manual, mechanically automated and digitally automated via DNC/CNC

- Control type for CNC Horizontal Mills: Number of axes, automated pallet changers (or no pallet changers), automated vs. manual tool changers

- Type of Mill: General purpose vs. single purpose configurations and toolroom vs. production machines

- Size: Micro, mini, benchtop, floor stands, large and gigantic

- Power Source: Line-shaft driven (not available anymore) vs. individual electric motors, hand-cranked (sometimes used by hobbyists) vs. electric power

Basic Components of a Horizontal Mill

Column: The support of the horizontal mill, may have a single or double column - this includes a heavy base and contains internal components such as oil and coolant reserves. Near the spindle, it usually holds the spindle motor.

Knee: This is an adjustable support to the table that holds the work piece. For certain machines, its adjustable along the Z-axis (as the table can be raised and lowered.)

Saddle: On top of the knee, a support to the worktable. This may move parallel to the axis of the spindle, moving the workpiece horizontally.

Worktable: Holds the workpiece with a vise or chuck or other means. This may be adjustable in any direction.

Spindle: The part of the machine that holds and spins the machine arbor. The column holds the motor that turns the spindle.

Arbor: The shaft which is inserted into the spindle. There are many types of arbors including the standard milling machine arbor, screw machine, slitting saw milling cutter and end milling cutter, for example.

Machine Tool: The part held by the spindle that removes the material (does the cutting). Many configurations are available, for example, plane, form relieved, double angle mills, twist drills, etc.

When selecting a Horizontal mill, take into consideration both your current and future needs for size, speed, versatility, power, and precision. Machines will vary by X, Y & Z travel, size, taper, the number of axes, the spindle rpm (revolutions per minute), spindle motor power, and tool capacity. For the right applications, a horizontal mill will provide many years of reliable service.