CNC Machine Welding

Manufacturing facilities depend on CNC welding machines to safely and reliably join components together without melting the base material. Welds can be applied to a range of materials such as metal, plastics and wood. Welds can be applied in different configurations depending on the final application.

CNC welding machines in particular allow every aspect of the welding process to be calculated, computer-controlled and automated. These machines will always apply welds in exactly the right position and with consistent quality. They come in a range of sizes and configurations so you can be sure to find the right machine for you. Welding machine manufacturers include Panasonic, GENESIS, HGTech, Miller Weldmaster, Heron and HSG.

Call us at (844) 262-6789 to find the right used CNC welding machine for you.

CNC welding machines for sale

CNC welding machines are categorized by the type of weld the machine performs and the material being welded. Most welding machines have one or more articulating arms attached to a bridge (horizontal or vertical), and are controlled by a central computer.

What are the types of CNC Welding Machines

There are many variations and sub-variations of welding machines, but here are the most common:

Spot welding

Spot welding is primarily used for sheet metal products or wire mesh. It uses electrodes to apply a powerful welding current to a small spot in a very short time. This allows the weld to occur without damaging the rest of the material. Spot welding machines are very popular in the automotive industry.

Seam welding

Seam welders have the welder run evenly along a beam for extended straight-line welds. They are cantilevered from one end to allow for the loading and unloading of the parent material. Seam welders are often used to weld tubes of varying diameters and lengths, and as such come in both circumferential and longitudinal configurations.

TIG welding

TIG welding machines use arc welding to make their joins. TIG stands for Tungsten Inert Gas. The electrode is made of tungsten, and is protected from oxidation by an inert gas like helium or or argon. The most common application for TIG welding machines involve joining stainless steel and non-ferrous metals.

Butt welding

Butt welding is used to connect the ends or edges of two parts together, where the connection angle is anywhere from 135 to 180 degrees. Butt welding is often applied to pipes or flanges.

Wedge welding

Wedge welding machines run between two overlapping sheets of material and heat the sides facing each other. Once the welder has heated the materials, the two sides are then pressed together and cooled to let the weld solidify. Wedge welds are often used when welding plastics like high-density polyethylene (HDPE).

Friction welding

Friction welding machines generate heat by mechanical friction. Two work materials are rubbed against each other until both sides have sufficiently softened. A lateral force called an upset is then applied to join the two surfaces and fuse them. Friction welding can be used on both metal and plastic, and is used in automotive and aerospace applications.

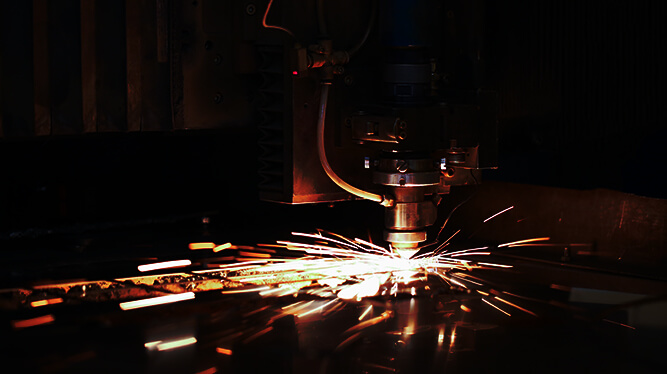

Laser welding

Laser welding uses a concentrated beam of light to generate enough heat to join metal or plastics together. Laser welds are generally used in high-volume applications that require a lot of automation. Fibre lasers are a variant of laser welding that use high-quality optical fibre to create the beam.

Selecting a used CNC Welding machine

When you buy a used CNC welding machine, you first have to analyze your own needs. Ask yourself questions like:

- What material am I working with?

- What kind of joint is being welded?

- Do I need this process to be automated?

- What are the age and capabilities of the PLC?

- What kind of support and documentation do I need?

- How easy or difficult is it to load the parent materials ?

If you need additional help finding the right welding machine, call us at (844) 262-6789.